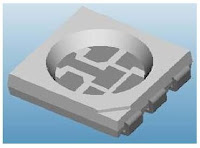

The SMD LED bracket is formed by PPA and metal. Normally, the bracket will be plated with silver to facilitate the light and connect with the LED gold wire. The functions of the bracket are carrying the chips, conducting the current, increasing the heat dissipation and protecting the internal structures.

|

| The bracket of SMD LED |

At present, the copper brackets and the iron brackets are the two main metal brackets in the industry. The resistivity and thermal conductivity of copper are 1.678 and 401 that are better than that of the iron's 9.71 and 80. We all know that the temperature is one of the major factors affecting the LED's life. The resistivity and the thermal conductivity of the bracket directly affect the lifespan of LED. The lower the LED resistivity, the higher the LED electro-optical conversion efficiency, the smaller the heat generation. The higher the LED thermal conductivity, the better the cooling effect.

It can be seen that the copper bracket is better than the iron bracket in quality. Besides, the high ductility of the copper brackets will also reduce the death rate of LEDs. Furthermore, due to the iron is easy to rust, once the iron is rusted, the silver-plated layer will fall off and the LED will be broken.

没有评论:

发表评论